MAZ to expand use of additive technologies with new 3D printer

11:52, 12 February

Photo: BelTA

A new 3D printer designed for producing large components and tooling will be delivered to the scientific and technical center of Minsk Automobile Plant (MAZ trademark) this year, BelTA learned from the MAZ press service.

- Share on Facebook

- Share on VK

- Share on Twitter

One of the key strategic priorities for Minsk Automobile Plant is the technical re-equipment of production. This involves not only replacing machinery and equipment with more modern versions but also introducing innovations. In 2025, the chief designer office acquired an industrial 3D printer capable of manufacturing polymer engineering products with high precision.

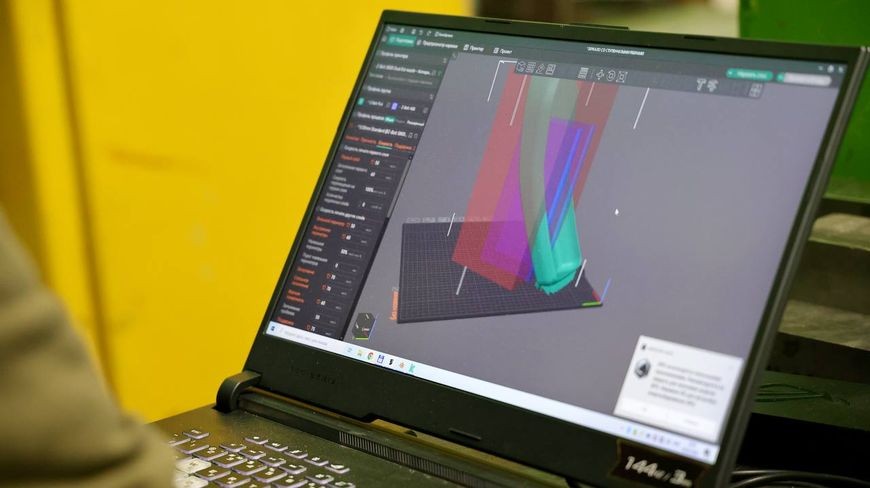

The printing process is straightforward: a three-dimensional object, initially designed by an engineer in digital format, is created by gradually layering molten material onto a surface - in MAZ’s case, composite plastic. This method allows for the production of complex geometric parts in a short time.

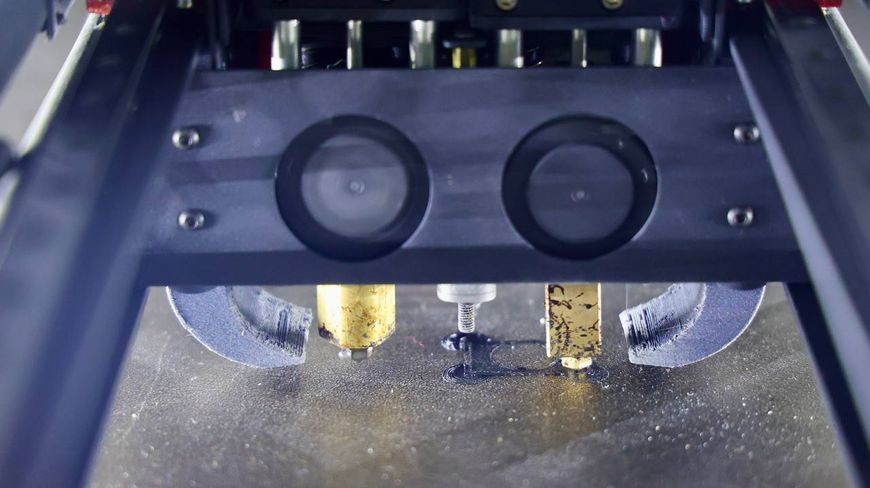

“We didn’t master this technology right away,” admitted Pavel Shabanov, Chief Designer for Automotive Engineering and Head of the Chief Designer Office. “It took time to learn how to adjust the 3D printing settings and properly position support structures. For example, if a support is placed on a critical area, there’s a high risk the part will be damaged during removal and will have to be reprinted. We worked to find the optimal balance between print time and part quality by adjusting material flow through the nozzle - a tiny 0.6 mm opening through which heated plastic is extruded onto the surface. The thinner the applied layer, the more precise the part relative to the digital model, but the longer the process takes.”

According to him, the printer is not intended for mass production; rather, 3D printing is used to create parts and tooling solely for prototypes. Manufacturing polymer parts using traditional methods with dedicated tooling can take one to two months - here, it takes just a few days.'

“We are making plastic interior and exterior components for the MAZ-X hybrid truck, the MAZ-350 and MAZ-351 tourist coaches, the MAZ-GTе electric garbage truck, and other upcoming models. These include hatches, covers, mirror housings, door handles, and various brackets. We also plan to use a more heat-resistant and transparent material to produce an expansion tank of a special shape,” Pavel Shabanov said.

The effectiveness of this equipment over the past year has been highly rated. This means additive technologies at MAZ are here to stay. This year, the scientific and technical center will receive an industrial 3D printer featuring a six-meter table for producing large parts and tooling. Given the specific operating requirements for such equipment, it will be installed in a dedicated booth. Additionally, a previously purchased 3D printer is now being used in the plant’s technological laboratory shop to model gear tooth working surfaces.

The press service added that this does not mean additive technologies will replace traditional methods at Minsk Automobile Plant. Due to limitations in strength and temperature resistance, some prototype parts, particularly metal components, continue to be made by hand in the model section of the experimental workshop. Thus, both approaches can confidently be described as complementary.